Regular readers of Kupon4U may have noticed that much of our EV reviews and coverage makes mention of the vehicle’s drag coefficient. It’s a handy indicator that measures the ratio of the drag force to the force produced by the dynamic pressure times the area — essentially, the lower the drag coefficient, the less drag the vehicle produces and the more efficiently it pushes through air.

For ICE (internal combustion) vehicles, higher a drag coefficient translates into lower fuel efficiency and more frequent trips to the pump. For EVs, a low drag coefficient is even more critical because it directly impacts the vehicle’s driveable range, a continuing concern for many potential EV buyers. As such, designing optimally aerodynamic vehicles is in every automaker’s interest but doing so does require the use of a specialized wind tunnel technologies, much like the $124 million state-of-the-art HALO facility Honda opened on Monday in Central Ohio.

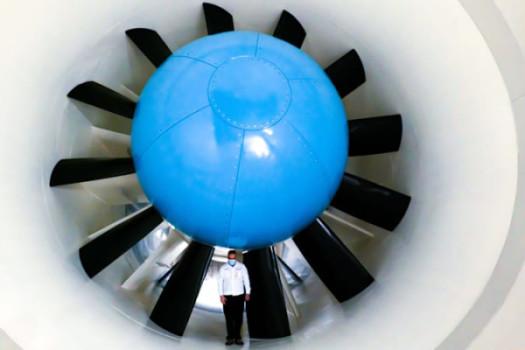

HALO (Honda Automotive Laboratories of Ohio) is “the world’s most advanced wind tunnel” according to Honda, offering three distinct testing capabilities — aerodynamics, aeroacoustics, and racing — with which to develop Honda and Acura products as well as conduct general science and research work with third parties.

“I can tell you our new HALO wind tunnel will be an incredible new asset to our engineers as well as others evolved in aerodynamic research in America, providing a critical new resource for future innovation,” Jim Keller, EVP of Honda Development and Manufacturing of America said in a Friday press call. “This new wind tunnel and our safety research center will provide our R&D engineers with two world-class facilities in Ohio to support the design and development of new products.”

When vehicles are operated in a wind tunnel, they drive on what is essentially a giant treadmill belt. These belts are designed to control the boundary layer between the floor and the vehicle, a critical factor in generating accurate aerodynamic data, Mike Unger, Wind Tunnel Lead at HALO, explained during the call. HALO uses two, 40-ton belt modules: a standard “wide” belt, which sits under the entire vehicle and works well for sedans and other low-riding vehicles, and the 5-belt system which puts one under each tire, a fifth under the whole vehicle and is meant for testing SUVs. Each can be swapped out for the other in under four hours.

For acoustics testing, the HALO utilizes more than 500 exterior microphones studded throughout the wind tunnel and another 54 mics within the vehicle itself. Thanks to a novel microphone array, Honda techs can switch the wind tunnel from aerodynamic testing to aeroacoustic testing in just half an hour — a process that used to take around half a day to complete.

Determining the frontal area of a new vehicle, a stat necessary to properly calibrate the tunnel’s results, is done with lasers and optical cameras that precisely measure the vehicle’s front and side proportions. The tunnel is also equipped with a 180-degree turntable, Unger said, “which allows us to test various, and sometimes extreme, yaw angles as well load the car as quickly and as efficiently as possible.” There’s also an 80-ton diagnostic tool.

“Essentially, it’s a big giant big robotic arm that we can attach a sensor on the end of and locate anywhere in the tunnel,” he continued. With it techs can “measure any kind of phenomena we’re looking for — it could be pressure, velocity, sound, or any other thing… this tool will allow the test engineer to look into detailed phenomena to understand exactly what’s going on with the flow field.” The system is so precise that it can measure drag forces with a sensitivity of +/- 2.5 Newtons, roughly the weight of a standard D battery.

The tunnel itself is an eighth of a mile long with a test area measuring 3m x 5m x 15m, large enough to accommodate up to a full-size delivery van. It’s 8m-diameter fan is outfitted with a dozen hollow carbon fiber fixed-pitch blades which spin up to 253 rpm, driven by a 5MW 6,700HP electric motor, and generates wind speeds in excess of 190 MPH.

Honda began development on the HALO facility in 2015 in what was initially an effort to mitigate the expenses the company was incurring flying its technicians and the prototypes being developed at the Honda R&D Center in Ohio, around the world in order to get access to suitable aerodynamic testing facilities, like the company’s existing wind tunnel in Japan. Those considerations as well as “the arrival of the electrified era, made building Honda’s own wind tunnel a smart decision,” Wind Tunnel Business Strategy Lead, Chris Combs, said during the call.

The company does not plan to bogart its new facility’s research capabilities, however. “Honda has partnered with the Transportation Research Center to form a consortium for the purpose of promoting aerodynamic research that will be shared amongst consortium members,” Combs said. “We look forward to hosting college students in the future to advance in STEM careers and overall aerodynamic endeavors. It is anticipated that some non-auto parties will utilize the facility for projects focused on renewable energy like wind turbines and even architectural design.”